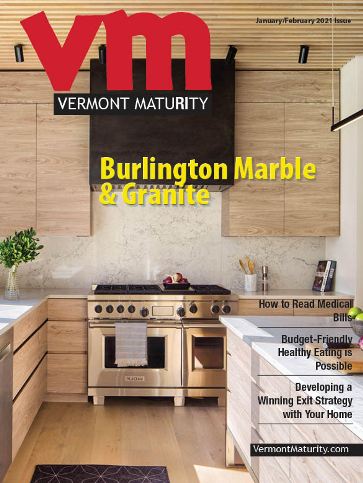

For the last 18 years, Burlington Marble & Granite has manufactured and installed the finest handcrafted stone countertops for many of Vermont’s premier builders, architects, fine kitchen and bath designers, and discriminating homeowners. Burlington Marble & Granite doesn’t sell cabinets or tile or appliances; they are strictly countertop experts. With over 100 years of combined experience, its staff of salespeople, installers, and shop personnel will thoroughly explain all of the different types of stone and quartz products and how each would work in a customer’s specific application. Do you want marble countertops in your kitchen but everyone else keeps telling you that you can’t? You can rely on BM&G’s experience to carefully walk you through the difference between marble and other materials and what to expect for years to come.

Burlington Marble & Granite applies the “Art of Stonecrafting” to natural and man-made countertop surfaces, including granite, marble, engineered stone (quartz), quartzite, limestone, soapstone, and slate. It also offers an extensive range of natural materials though its alliances with the Northeast’s largest stone slab suppliers, including Marble and Granite Inc. Additionally, it offers engineered quartz-stone material, manufactured by Vadara, CaesarStone USA and many more. Burlington Marble & Granite has the widest variety of materials available from slab importers throughout the entire Northeast. Its warehouse in Shelburne typically stocks 50 or more colors of full slabs in varying materials.

“When we developed the slogan, the “Art of Stonecrafting”, we were really old-school craftsmen using very traditional tools and methods to fabricate stone. We still are old-school craftsmen, of course, but now we’ve gone completely digital, which is an entirely different art in and of itself.”

Mike Richburg, Owner

In 2016, Burlington Marble & Granite moved to its current location in Shelburne. It was there that it transformed into a fully-digital shop, complete with two computer numerical control machines (CNCs), a laser templating system, and a state of the art high definition slab layout station. The Slabsmith, as it’s known, allows customers to better visualize the project and, with the assistance of Burlington Marble & Granite’s staff, carefully lay out every inch of the countertops. All in all, the digitalization helps streamline the “Art of Stonecrafting” into a more efficient and interactive process. The typical stonecrafting process at Burlington Marble & Granite involves four steps: estimating, templating, fabrication, and installation.

Estimating

In the first step of the process, Burlington Marble & Granite quotes the project based on the customer’s initial selection of stone material and the drawings. In some cases, a representative will visit the home or job site and provide a quote based on the site and project requirements.

For most estimates, a customer will need to provide a layout drawing of the countertop surface or have a representative visit his or her home or job site. The customer will also need to specify an edge profile, provide sink and fixture specifications, and relay any custom requirements.

Templating

Once a customer has selected a material and the estimate is accepted, a representative from Burlington Marble & Granite will visit the home or job site to create a project template.

The template is made using a highly accurate laser templator. This process creates a “duplicate” of the surface configuration, which reproduces angles and radii and shows the sink and other fixture locations. During the template process, notations about edge profiles, backsplashes, and/or other job requirements are recorded.

During the template phase of the process, Burlington Marble & Granite may ask the designer, homeowner, or builder to make the sink and fixtures available. This is to ensure a perfect fit with the template before the fabrication process.

Fabrication

Once the templating is complete, the file is edited to insure accuracy of the final fit and then sent off to a programmer. The digital templates can then be overlaid onto a high resolution photo of the customer’s slab and then manipulated to insure that the most beautiful parts of the stone are being highlighted. Once this layout is approved by the customer the job transitions into production where a combination of the 2 CNC machines fabricates the countertops to the precise measurements of the templates. Occasionally, a stoneworker needs to complete the final stage of the fabrication process doing some of the more intricate details that the CNCs cannot with handheld grinding and polishing tools

Installation

A typical slab weighs between 200 and 600 pounds, which makes bringing a piece of granite countertop into a house no easy feat. However, Burlington Marble & Granite has experience dealing with slabs as large as 1,200 pounds. Once the slabs are in place, a team of skilled craftsmen will complete the final trimming and fitting. The sink is mounted underneath the new countertop and is permanently attached. Amazingly, what began as a massive slab of stone in the yard is transformed by Burlington Marble & Granite’s “Art of Stonecrafting” into an expertly installed, stunning countertop.

When looking for the absolute best custom countertops Vermont has to offer, look no further than Burlington Marble & Granite. From its extensive combined experience, to the state of the art, fully digitalized shop, the folks at Burlington Marble & Granite will provide not only the highest level of customer service, but also the highest quality natural and man-made countertop surfaces. When shopping for a countertop, a customer can rest assured Burlington Marble & Granite will provide the very best materials and the best craftsmanship for the job.

For more information visit BurlingtonMarbleAndGranite.com or call 802-860-1221.

Related Articles & Free Vermont Maturity Subscription

Cooking Up New Ideas in Modern Kitchen Design

How to Make Your Kitchen Safer and Easier to Use

Comment here